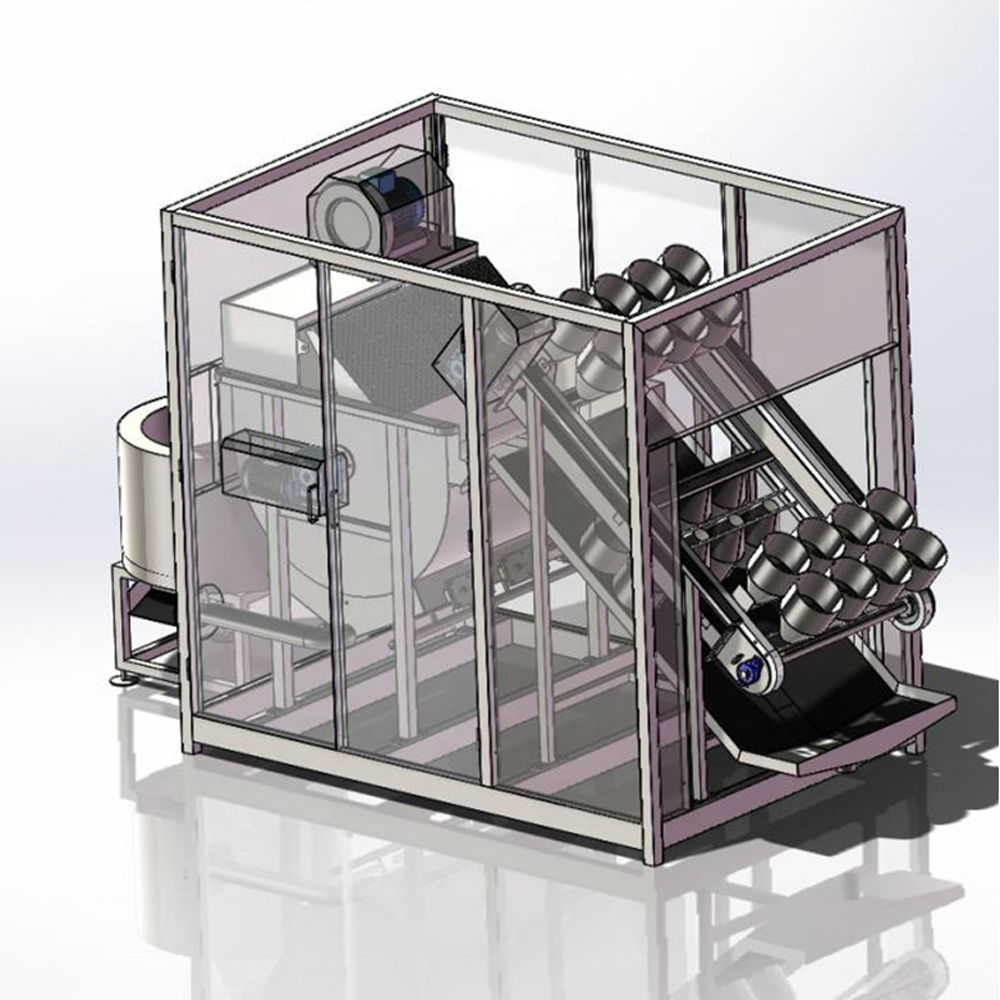

Compact processing line is a completed and integrated poultry processing line, which capacity is from 300bph to 1000bph. It is designed for small investment and convenient installation purpose, assembled and tested in the factory, Mobile easy clean operation and maintenance.

I. Advantage of Super Compact Poultry Processing Machine

For small poultry processing companies, this bleeding & scalder & plucker compact.

system can effectively reduce the manpower.

This system is start working with birds receiving for automatic bleeding, scalding, and plucking, the whole process is automatic working.

The system is driving with frequency converting system, the scalder is working with electric heating system, the data can be set according to client’s working capacity.

This system is suitable for working at high labor cost area or small poultry processing plant, the capacity can reach up to 300 birds/Hour.

II Composition of product

Bleeding & scalder & plucker compact system is combined with bleeding, conveying,

electric heating scalder, unloading from scalder, plucking and control system.

1.Bleeding and conveying system

Bleeding and conveying system including bleeding cone, motor reducer, conveyor rack

and chain system There is one switch at bleeding conveyor which is L J18A38J/EZ

2,Scalder and Its conveying system

Scalder includes water tank, electric heating pipe, water level control, temperature

control, air fan, motor reducer, and conveying … etc.

There is one switch at bleeding conveyor which is L J18A38J/EZ

3,Plucker and door opening device

Plucker includes plucker and its pneumatic door.